PCB Components Management

PCB (Printed Circuit Board) Components Management encompasses the coordination and control of electronic components used in the assembly of printed circuit boards. It involves sourcing, procurement, inventory management, and optimization of components to ensure efficient production processes. This includes managing supplier relationships, maintaining adequate stock levels, and implementing strategies to address challenges such as component shortages and obsolescence. Effective PCB Components Management is essential for the timely and cost-effective assembly of electronic devices.

PCB Manufacturing Services

PCB Manufacturing Services refer to the suite of processes and expertise involved in the production of printed circuit boards (PCBs). These services typically encompass the entire PCB fabrication process, from design validation and prototyping to mass production. They may include services such as PCB layout design, PCB assembly, surface finishing, quality control, and testing. PCB Manufacturing Services are vital for electronics companies looking to outsource the production of their circuit boards to specialized facilities with the necessary equipment and expertise.

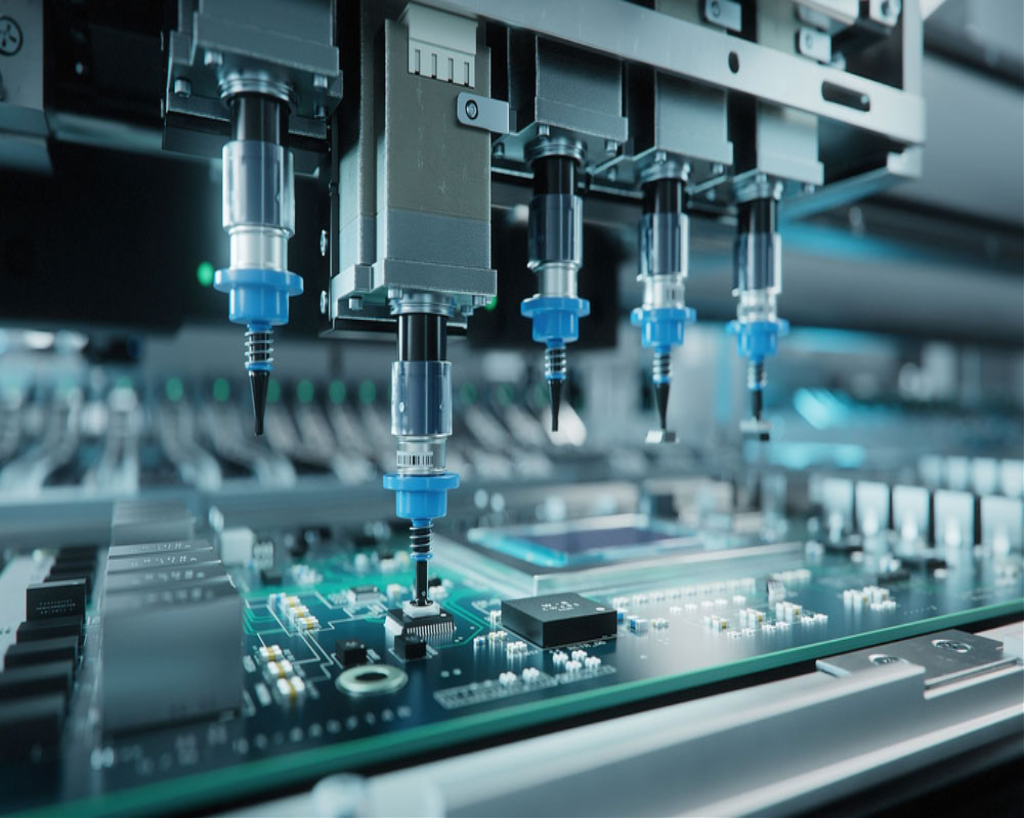

PCB Assembly Services

PCB Assembly Services involve the process of assembling electronic components onto printed circuit boards (PCBs) to create functional electronic devices. These services typically include surface mount technology (SMT) assembly, through-hole assembly, and sometimes mixed-technology assembly, depending on the specific requirements of the project. PCB Assembly Services often encompass component sourcing, PCB fabrication, component placement, soldering, inspection, and testing. These services are crucial for electronics manufacturers seeking efficient and reliable assembly solutions for their products.

About Us

SMTWISE Tech INDIA Private Limited established in Noida, INDIA in 2024 as a Professional PCB & PCBA EMS Manufacturer focusing on providing one-stop service - Redesign or UP-Gradation, Material Sourcing, PCB Fabrication, SMT, THT & Mixed Assembly, IC Programming, Function Test, Mechanical Assembly

We’ve helped many companies, both domestic and international. Our manufacturing services go beyond PCB and PCBA – we can handle additional requests, redesigns, and modifications to meet our clients’ needs. Our professionalism and work ethic are recognized by industry leaders in microelectronics.

SMTWISE Tech INDIA Private Limited specializes in providing cost-effective PCB assembly solutions with a focus on quality. Our expertise lies in offering comprehensive PCB assembly services tailored to meet the specific needs of our clients. From sourcing high-quality components to utilizing advanced assembly techniques, we ensure that every aspect of the assembly process is optimized for efficiency and reliability. Our commitment to quality is unwavering, and we employ rigorous inspection and testing procedures to guarantee the performance and durability of the final product. With SMTWISE Tech, you can trust that your PCB assembly needs are in capable hands, delivering exceptional value without compromising on quality.

Services

SMT (Surface Mount Technology):

In SMT, electronic components with flat leads are soldered onto the PCB surface. This is a high-speed, automated process suitable for small, lightweight components.

Material Sourcing:

Here, all the electronic components and materials required for the PCBA are procured from qualified vendors. This ensures that the quality and specifications meet the design requirements.

PCB Fabrication:

This involves manufacturing the bare PCB based on the design specifications. It includes processes like drilling holes, plating, and laminating various layers of the board.

Redesign or UP-Gradation

This stage involves revisiting the design of the PCBA to improve functionality, reduce costs, or incorporate new components.

THT (Through-Hole Technology):

Through-hole components have wire leads that pass through holes in the PCB and are soldered on the other side. This method is often used for larger, bulkier components that require more robust connections.

Mixed Assembly:

This combines both SMT and THT techniques on the same PCB to take advantage of the strengths of each method.

IC Programming:

Some integrated circuits (ICs) require pre-loading specific software or firmware before they can function properly. This programming is typically done by the manufacturer or a service provider.

Function Test:

After assembly, the PCBA undergoes rigorous electrical testing to ensure it meets the designed functionality and performance specifications.

Mechanical Assembly:

This is the final stage where the PCBA is integrated with other mechanical components, enclosures, and connectors to form the final product.

Contact

Contact us for expert solutions in redesign, material sourcing, fabrication, assembly & testing!

Location:

SMTWISE TECH INDIA PVT LTD - B 110, 1st floor, Secter 88 Block B Rd, Block C, Sector 88, Noida, Uttar Pradesh 201301

Tech Support Email:

smtwisetech@gmail.com

Call:

+91-7210701090